Our Comprehensive Services

At Omega NDE Solutions, we offer cutting-edge non-destructive inspection services tailored for the oil and gas industry. Whether you are seeking to enhance safety, ensure compliance, or maximize operational efficiency, our solutions are designed to meet your unique challenges.

With a commitment to excellence, we empower your business to succeed by providing precise and reliable inspections. Trust us to convey your narrative of safety and innovation through our expert services.

ADVANCED NDE SERVICES

Phased Array (PAUT)

Accuracy and Reliability: Phased array technology provides highly accurate and reliable detection of flaws, such as cracks, inclusions, and voids, which might not be visible using other inspection methods.

Corrosion Mapping: Equipped with a full range of scanners and probes, our PAUT equipment is capable of providing real-time data of internal corrosion, pitting, and other defects with greater accuracy.

Detailed Imaging: The ability to create detailed cross-sectional images (via A/B/C & S scans) of the inspected material helps identify issues before they become significant problems.

Full Matrix Capture with Total Focusing Method (FMC / TFM)

All-Angle Inspection: FMC/TFM enable inspection from all angles and depths simultaneously, providing a complete view of the test material without the need for multiple scans. TFM processes this data to create highly detailed, high-resolution images of the inspected material.

Higher Sensitivity: Provides greater sensitivity for detecting small and critical defects. Provides detailed imaging to accurately characterize defects in terms of size, type, orientation, and location.

High Temperature Hydrogen Attack (HTHA) Inspection

Our Lavender certified technicians utilize a suite of inspection technologies (PAUT/TOFD) to identify and manage the risks associated with high temperature hydrogen environments which can lead to serious damage to materials, degradation of mechanical properties and potential catastrophic failures.

Pulsed Eddy Current (PEC/PECA)

Comprehensive Area Coverage: PEC can penetrate through coatings and insulations without needing their removal, reaching significant depths to detect subsurface anomalies and corrosion.

Scab/Blister Corrosion Assessment: Assess material integrity through scabs and blisters without removing metal that could potentially create hazards.

Magnetic Flux Leakage (MFL)

Critical Zones in Tanks: MFL is highly effective in detecting corrosion, pitting, and other surface-breaking defects in the steel plates of storage tanks. Also capable of providing tank floor top/bottom corrosion discrimination.

Inspect Through Coatings: MFL can be performed without removing coatings, linings, or thin non-magnetic coverings, reducing preparation time and preserving protective layers.

Alternating Current Field Measurement (ACFM)

Fatigue Cracking: ACFM is highly effective at detecting surface-breaking cracks, which are common in structures subjected to repetitive stress and fatigue loading.

Cost Effective: Has the ability to detect cracks without requiring the removal of coatings and can be done on in-service welds up to 500degF.

NDE AND TECHNICAL SERVICES

Ultrasonic Testing (UT)

(Shear Wave /Thickness)

UT shear wave is highly effective for detecting internal flaws such as cracks, voids, inclusions, and other discontinuities within materials.

Corrosion and Erosion Monitoring: UT is also commonly used to measure the remaining wall thickness of pipes, tanks, vessels etc. to monitor for corrosion or erosion, ensuring they remain within safe operational limits.

Conventional NDE

Our range of offerings include:

Magnetic Particle Inspection (MPI)

Dye Penetrant Testing (PT)

Positive Material Identification (PMI)

Portable Hardness Testing (HT)

Ferrite Testing (FT)

API / NACE / AWS Inspectors

Our certified inspectors play a crucial role in ensuring the integrity, safety, and reliability of equipment. We offer the services of:

API 510 Pressure Vessel Inspectors

API 570 for Pressure Piping Inspectors

API 653 Above Ground Storage Tank Inspectors

API 580 Risk Based Inspectors

AMPP (NACE) Coating Inspectors

AWS (CWI/SCWI) Certified Welding Inspectors

Fitness for Service (FFS)Assessments

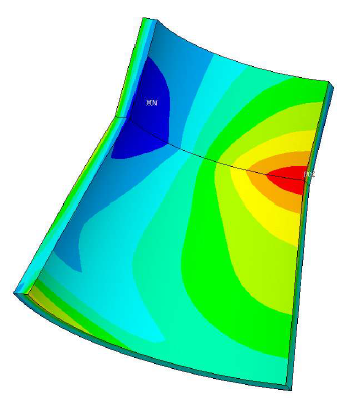

Our highly trained professional engineers perform FFS assessments with the help of advanced analytical software tools to ensure the integrity and safety equipment by evaluating damage from corrosion, temperature fluctuations, or mechanical stress.

Flange Management

Our flange management services can help improve:

Operational Efficiency: Effective flange management reduces the likelihood of leaks and failures, minimizing unplanned shutdowns and associated downtime.

Cost Savings: Preventing leaks and failures through proper flange management can significantly reduce repair/rework costs.

Safety: Proper flange management reduces the risk of leaks, which can lead to hazardous conditions, environmental contamination, and safety incidents.

Asset Integrity Management

Turnarounds (TAR) or shutdowns are complex and significant events in the lifecycle of industrial facilities and our certified and competent engineers/inspectors offer several benefits:

Pre-TAR activities such as preparation of equipment inspection packages.

TAR activities encompassing the coordination of site operations, conducting inspections, and ensuring proper quality assurance and control.

Post-TAR activities such as ensuring comprehensive documentation is in place for future reference and meets regulatory standards.